As businesses become increasingly reliant on technology and advanced equipment, the importance of maintaining accurate and reliable measurements has become more critical. Hence, ISO calibration is critical to ensuring global uniformity and consistency.

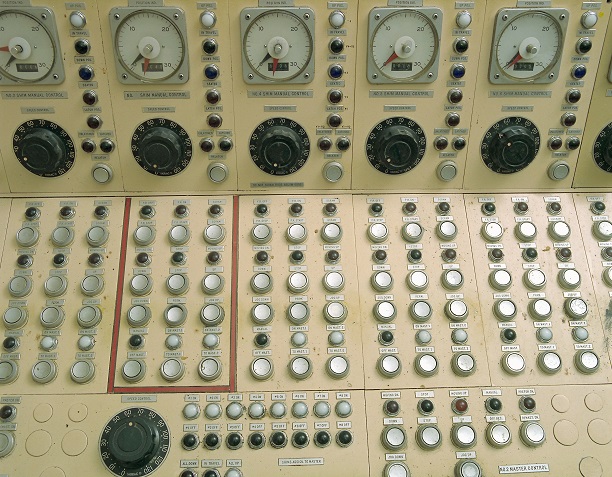

ISO calibration can be described as a process that ensures the accuracy and reliability of measurement equipment by comparing its readings to a traceable standard. It involves a rigorous process that matches measurement equipment to the known reference standard to determine its accuracy and reliability.

ISO calibration is critical for businesses such as manufacturing, pharmaceuticals, and the automotive industry that rely on accurate measurement data to make crucial decisions. Calibration ensures that data collected are reliable, as even a slight deviation in any measurement can have significant consequences.

According to Endeavour Technical Limited’s Compliance Director, Richard Keen, by following ISO calibration guidelines, businesses benefit from improved efficiency, quality, and customer satisfaction. It is also good practice to identify a calibration supervisor responsible for ensuring that all required measurements are taken, and equipment is regularly calibrated.

The quality assurance department is responsible for designing, implementing, and maintaining the calibrated equipment procedure. It is also responsible for calibration administration responsibilities as defined by Endeavour Technical Limited’s guidelines. Within the organisation, each section has a person in charge who is directly accountable for any defective equipment or inaccurate data provided to the organisation.

For more information, visit https://www.iso-9001-checklist.co.uk/calibrated-equipment-procedure.htm

Based on Endeavour Technical Limited’s guidelines and checklist, the Calibrated Equipment Procedure can be implemented in 6 simple steps.

The first step is to identify the equipment to be tested. It’s important to know how frequently each piece of equipment is used by the company’s personnel.

The second step is to identify the Inspection and Measurement Processes. This entails setting up s procedure to be able to trace each piece of equipment through its calibration record.

The third step is to decide on the Calibration Frequency. The quality assurance department ultimately decides which frequency calibration should occur, depending on the equipment and its usage.

The fourth step is to assign responsibilities. The selection and training of competent calibration personnel is an important consideration and the personnel involved must possess adequate technical education and experience in the area assigned.

The fifth step is to decide on the Custody of Calibration Tools. This step entails establishing and maintaining environmental controls to ensure that monitoring and measuring instruments are calibrated and used in conditions that will not adversely affect the accuracy of the measurements.

The final step is to identify the Relevant Standards. Endeavour Technical Limited’s guidelines and templates help clients determine the most appropriate procedure to meet their requirements.

There are many benefits to having a calibrated equipment procedure in place. All personnel involved will be familiar with maintaining accuracy throughout the testing stages, reducing the risk of inaccurate documentation. It ultimately inculcates a higher standard among technicians and provides an audit trail for any future changes, modifications, or additions to the equipment.

All monitoring and measurement equipment and software performance data shall be reviewed by the Quality Manager. Audits of maintenance procedures and records should evaluate the adequacy of safeguards, change controls, and other controls necessary to maintain software quality and proper performance of associated equipment.

About the Company:

Endeavour Technical Limited is an ISO company based in London, UK. The company is dedicated to writing and developing ISO templates for customers worldwide. Endeavour Technical Limited is committed to providing high-quality products and services and excellent customer service. ISO-9001-Checklist.co.uk is a leading provider of quality management resources, including checklists, templates, and guides for ISO 9001 compliance.

Media Contact

Company Name: Endeavour Technical Limited

Contact Person: Richard Keen

Email: Send Email

Phone: 0845 054 2886

Address:71–75 Shelton Street, Covent Garden

City: London WC2H 9JQ

Country: United Kingdom

Website: https://www.iso-9001-checklist.co.uk/